VIDEO - Click here to see a short video of

the first test run of my tesla coil with set discharge point

VIDEO 2 - short clip of coil with no

particular discharge point

|

|

Overall picture of tesla coil almost done. |

|

|

|

| To wind the 1400 turns on the secondary 4" PVC form, I borrowed my wife's quilt holder! Made a great support! I used two 4" PVC end caps with a bolt in each end. | The long process of winding the coil has begun. Every inch or so I taped the wire so if the wire slipped out of my hand (which happen a few times), I wouldn't have to start all over again. The secret to winding the wire is to keep the wire taught and feed it at an angle, not straight across from the supply spool. |

|

|

| Bought a cheap piece of wood at Home Depot and made a quick base for the coil. | I made the spark gap out of two 5/16" carriage bolts, right angle brackets and 2 insulators. |

|

|

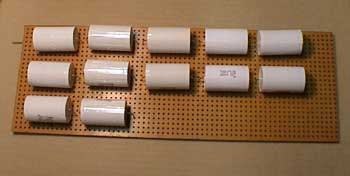

| The capacitor bank was assembled on pref board. Twelve 0.15uf, 2000v poly caps were used to produce a MMC of 0.0125uf at 24,000 volts. | There is a 10 megohm bleeder resistor across each cap. |

|

|

| My temporary primary coil is made of about 14.5 turns of #14 high voltage wire temporally taped to a piece of cardboard. Later I plan to use 1/4" copper pipe. | The primary and secondary coils rest on the top section and the power transformer, spark gap, etc are below, shielded from the high voltage secondary. |

|

|

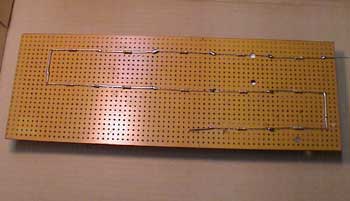

| View of the underside showing component layout and wiring. High voltage 15,000 volt wire used everywhere. | The secondary coil with 1450 turns of #28 magnet wire covered with varnish on a 4" PVC pipe. |

|

|